Introduction

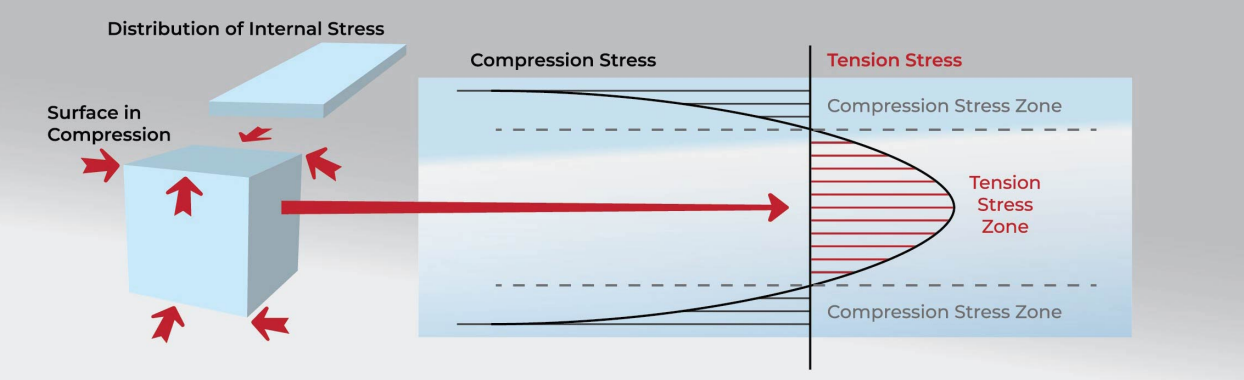

Nam Heng ( NHG ) Tempered glass is made by heating flat glass to just below its softening tempereature and suddenly chiling it with jets of cold air. It results the outer skins under powerful compressive stress and the interior with severe tensile stress. Inconsequence, the impact applied to the glass will be overcome by the compressional stress on the surfaces to assure safety of use. We are able to supply heat treated safety glass from 4mm to 25mm on normal clear glass, tinted glass and Super Low-E with the size up to 2.8m X 6m.

A latest technology of Tamglass-RC350 tempering line (Vortex Plus-latest tempering technology for excellent quality) and a full force convection line which able to produce all kind of safety glass that needed heat treatment for building application with excellent quality.

Characteristics

What

A type of safety glass created with controlled chemical or thermal treatments to increase its strength when compared to annealed or “normal” glass.

Why

Nam Heng ( NHG ) Tempered glass is four to five times stronger than annealed glass which makes it desirable in transportation, architectural and a variety of other applications. In addition, its balanced internal stresses enable the glass, when broken, to crumble into small, harmless “chunks” instead of splintering into sharp, jagged shards./p>

How

Flat glass is heated to 700 degrees Celsius and then cooled rapidly, or “quenched,” with concentrated air currents, manipulating temperature and pressure (at times greater than 10,000 psi) to achieve the desired properties. The cooling differential created between the surface and central layers of the glass creates surface compression and internal stresses which underly the enhanced strength.